High-temperature lubricant paste HSP 1400

High-temp. lubricant paste HSP 1400 NSF

ASMBYPAST-HSP1400-AEROSOLCAN-300ML

Register now and access more than 125,000 products

- For universal use, supple and highly adhesive

- Ensures ease of movement and minimal wear thanks to high pressure load capacity

- Prevents corrosion, seizing and burning on

- Ensures uniform loosening of screw connections, ideal as separating paste for stainless steel screw connections

Safe for health

Non-toxic, no metallic pigments and free from graphite, MoS

2 and additives containing sulphur

Silicone-free

NSF H2 registered (no.: 150178)

Not suitable for lubricating bearings. Contains no metallic pigments and is free of MOS2 and sulphur-containing additives.

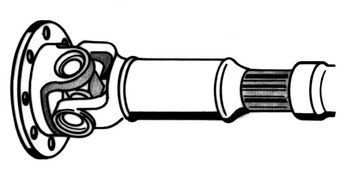

Splined shafts and joints of all kinds

Splined shafts and joints of all kindsHigh pressure load capacity ensures smooth running and minimal wear

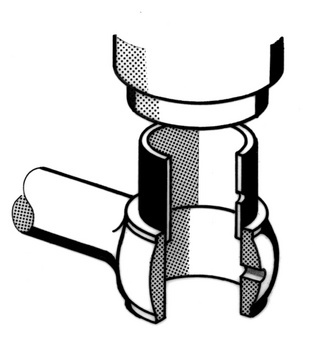

Sliding and rolling bearings, impellers and impellers

Destruction-free pressing in and out.

Operational readiness

Protection of edges from wear and seizing

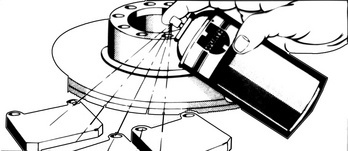

Brake linings

- Prevents corrosion and seizing of disc brake pads and deposits being burnt on

- Prevents squeaking and wear

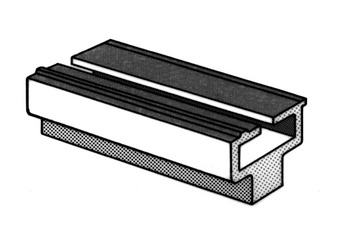

Press connections for slide guides, bed rails, column guides

- Even, jerk-free movements even at low speeds.

- Emergency running lubrication for additional lubrication with grease or oil.

- Protected against moisture

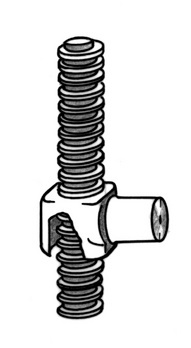

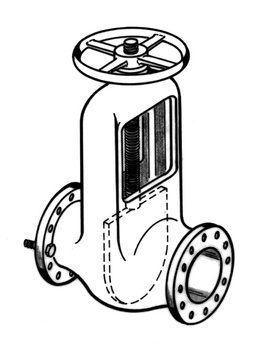

Shut-off valves, taps, slide valves

- Smooth movement of adjustment spindles.

- Uniform tightening torques and destruction-free dismantling of screw connection.

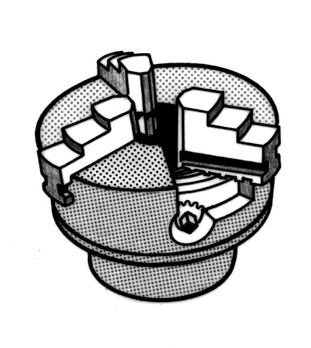

Brake parts, chucks, heavy clamped connections

- Ensures high clamping forces

- Ensures uniform tightening and loosening

- Highly adhesive, water-resistant lubricating film

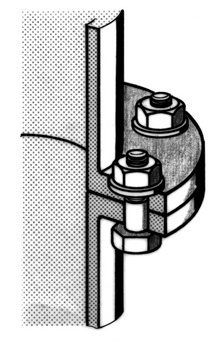

Flange connections, pins, screws, bolts and nuts

- Ensures even tightening torques due to low dispersion of the friction values

- Non-destructive disassembly even after long temperature exposure

- Prevents seizing, e.g. with stainless steel screws

NSF H2 registered (no.: 150178)

The usage instructions are recommendations based on the tests we have conducted and on our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting with deliberate intent. We ensure the consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

Ideal as separating paste for stainless steel screw connections, flange connections, pins, bolts and nuts, all kinds of splined shafts and joints, moving brake parts (not for friction surfaces), crimped connections for journal and roller bearings, flywheels and impellers, heavy-duty stroke spindles, guide slide bearings, guiding ways, pillar guides etc.

Cleaning surfaces of all types of residues (oxide, paint and scale layers, old lubricants). Mechanical action (wire brush) and/or using a cleaner recommended. Thin-film lubrication of threads and surfaces exposed to loads: Apply evenly with a brush or spray over the entire surface. Do not use like grease.

Chemical basis | Mixed synthetic mineral oil with organic thickener and white solid lubricant combination |

Colour | Grey |

Smell/fragrance | Characteristic |

Density | 0.973 g/cm³ |

Min. processing temperature | 0 °C |

Max. processing temperature | 40 °C |

Min. temperature conditions | -40 °C |

Max. temperature conditions | 1400 °C |

Min./max. friction | 0.1-0.13 µ |

Min. friction | 0.1 µ |

Max. friction | 0.13 µ |

Friction force | 450 N |

Friction force conditions | Friction cylinder/plate, 1000 µm, 50 Hz, 2 hours |

VKA load according to four-ball test | 3800 N |

Conditions for VKA load according to four-ball test | in accordance with DIN 51350-4, VKA test (Institute for Internal Combustion Engines) |

VKA welding load | 4000 N |

Conditions for VKA welding load | in accordance with DIN 51350-4, VKA test (Institute for Internal Combustion Engines) |

Wear depth | 0.3 µm |

Resistance in salt-spray test | 500 h |

Conditions for resistance in salt-spray test | in accordance with DIN 50021 |

Silicone-free | Yes |

Resistance against | Salt water, Acid |

VOC concentration (CH) | 69.52 % |

Contents | 300 ml |

Container | Aerosol can |

Shelf life from production | 24 Month |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!